PTFE Rotary Seals

What Is a PTFE Rotary Seal?

Your typical rubber or polyurethane rotary seals are made of soft, resilient materials known as elastomers. While they can be great for some seal applications, those rubbery materials are still prone to wear quickly, simply due to their soft nature. Rotary seals by Atlas Seals are made of PTFE, a semi-rigid thermoplastic which outlasts elastomer rotary seals especially in high stress applications.

PTFE Seal Applications

Rotary seals are needed when tough application conditions exceed the capabilities of elastomeric (rubber or polyurethane) seals. Some of these conditions include:

- Extremely high temperatures or extremely low temperatures

- Abrasion from high-speed applications

- Highly intense pressure

- Tough environments with chemical exposure or abrasive media

- Long life or low friction requirements

- Dry running without damage

The mechanics of spring energized PTFE seals operate on essentially the same principles as other radial seals. The key difference comes from the way that they are precision machined from amazing materials and utilize clever metallic locking bars to provide a guaranteed leak-tight seal where other seals fail. We offer tons of different PTFE seals and high-performance plastics for the outer portion of our seals as well as different types of springs, which we match up with each individual order based on the intended application.

PTFE Seal Types

Flanged Heel Spring Energized PTFE Seal

Ring & Energizer PTFE Seal

Stretch Formed Lip Seal – Lockstep™ Version

Stretch Formed Lip Seal – Lockstep™ Version

Spring Energized PTFE Rotary Seals

Unlike typical rubber or polyurethane rotary seals which have resilient (rubbery) materials, spring energized PTFE seals can use special plastics to perform at higher levels. By utilizing a separate metal spring for resilience, our PTFE rotary seals provide more consistent long term sealing force. For more details on the nuts and bolts of how they work go to the Spring Energized Seal page.

Spring energized rotary seals operate the same way, but with some added design features to prevent counter rotation. A few rotary seal design modifications to prevent counter rotation include:

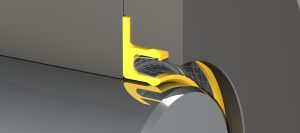

Flanged Heel Spring Energized Seals

The flange of the rotary seal is designed a little thicker than the counterbore that it sits in. A gland cap is then bolted to the hardware such that the thicker flange is trapped like a gasket which prevents the PTFE seal from rotating.

Static O-ring Spring Energized Seals

In some cases, the hardware will not allow for a flanged seal gland to be used. In these cases, the simple solution is to include a groove on the static side’s surface that will house an O-ring. O-rings have higher friction than PTFE, so they grip better and can prevent counter rotation in most cases.

Keep in mind that this option will also require a two-piece gland so that the seal can be installed, and the system pressure doesn’t just pop it out.

Lockstep™ Spring Energized Seal

This design is part of the family of Lockstep™ Rotary Shaft seal family so it is covered in depth on its own page.

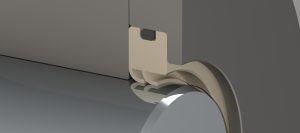

Ring and Energizer PTFE Seal

The Ring and Energizer PTFE seal design is as basic as they come. It is a double acting or bi-directional rotary seal.

The ring is the dynamic portion of the rotary seal and is made from PTFE or another durable, machinable plastic. The O-ring acts as a static seal between the PTFE seal ring and the rotary seal gland. This design, like the others, can be designed as dynamic on the inside or the outside.

Ring & Energizer PTFE Seal

Stretch Formed Lip Seals

Stretch formed lips seals are incredible rotary seals used in very high speed and low to no pressure applications. The lip seal is machined like a flat wash where the inside diameter is smaller than the shaft. The “flat washer lip” is stretched over a cone and packaged on a paper tube until it is installed. The stretched lip provides an excellent low friction seal that will last a long time as long as the dynamic surface is made to our specifications. If you are like us and love nerdy engineering stuff, keep scrolling to the bottom for an in-depth, comprehensive explanation on how these rotary seals work.

There are three design options for stretch formed lip seals available at Atlas Seals:

Stretch Formed Lip Seal – Static O-Ring Version

The static O-ring version is a no-frills lip seal. It is basically a square cross section of PTFE with a stretched formed lip. There is a groove on the outside where an O-ring hangs out to provide a static seal and help prevent Counter rotation. Keep in mind that this option requires a two-piece gland so that the seal can be installed, and the system pressure doesn’t just pop out.

Stretch Formed Lip Seal – “Canned” Version

The “Canned” PTFE stretch formed lip seal. This rotary seal works the same as the above basic static O-ring stretched formed lip seal, but it can be installed into and “open” one piece gland and it will not pop out. This design is an assembly of two “L-shaped” metal pieces called “cans”, a Stretched Formed PTFE seal lip, and a gasket. The gasket, PTFE seal lip and the inner can are housed inside the larger outer “can” that is designed to “press-fit” into the open gland. The press fit prevents the seal from counter rotating and popping out of the gland.

Stretch Formed Lip Seal – Lockstep™ Version

The Lockstep™ PTFE stretch formed lip seal: basically, it’s awesome! This design is a fully machined PTFE seal body that does not have metal “Cans” but can be installed in open glands without counter rotating or popping out. This design is part of the family of Lockstep™ Rotary Shaft seal family, so it is covered in depth on its own page.

Labyrinth PTFE Seals and Bearing Isolators

Labyrinth PTFE seals and bearing isolators are clever alternatives to a dynamic positive seal. They are used in low to no pressure applications where a leak tight seal is not needed- for example, keeping an oil mist from rapidly escaping the inside of a transmission or spindle.

These rotary seals have a PTFE seal ring that fits into a groove on the body of the seal. The PTFE seal ring is designed with a stretch fit on the shaft in which when running the seal ring spins with the shaft. The sealing surface is now the downstream face of the seal ring that is dynamic on the stationary seal body.

It is referred to as a labyrinth because of the path the fluid needs to take to make its way through the rotary seal. When the seal ring is spinning, the fluid it is in contact with must overcome the centrifugal force created by the seal ring it is adhering to. With each additional seal ring it becomes more and more difficult for a fluid to make its way through the labyrinth.

Depending on the application needs, this PTFE seal can be designed with only one seal ring or as many as needed to do the trick. Our imaginations are only limited by what is allowed by the applications hardware specifications.

There are a few ways a labyrinth seal can be trapped into its gland, but here are the two most common:

Static O-Ring Labyrinth PTFE Seal

The static O-ring version is the more basic of the two. There is a groove on the outside of the PTFE seal body where an O-ring hangs out to provide a static seal and help prevent counter rotation. Keep in mind that this option requires a two-piece gland so that the seal can be installed, and the system pressure doesn’t just pop out.

Lockstep™ Labyrinth Seal

The Lockstep™ Labyrinth Seal is incredibly efficient as it doesn’t require a two-piece gland to keep from popping out. We think it’s awesome. This design is part of the family of Lockstep™ Rotary Shaft seal family, so it is covered in depth on its own page.

How a Stretched PTFE Lip Rotary Shaft Seal Works

Instead of using a metallic spring to press on a seal lip and create the seal barrier, a PTFE stretched lip shaft seal uses potential energy that comes from its shape. PTFE has a heating-responsive shape Memory (HRSM), meaning when stretched from its free state the introduction of heat will activate its memory and it will attempt return to its original free state shape. The PTFE seal lip is simply a flat disk like a washer where the inside diameter of the disk is machined smaller than the diameter of the shaft it will be sealing on. The combination of the bend radius created by the body of the seal and the stretch of the lip creates a wide lip to shaft contact pattern. The PTFE seal lip HRSM is activated by friction heat generated from the rotating shaft. The seal flat contact pattern lip will try to return to its smaller inside diameter free state and lightly squeeze on the shaft. The wide contact pattern and low lip force reduces the wear rate by lowering the unit loading. This allows us to seal at much higher surface speeds as the pressure variable “P” is very low in the limiting Pressure Velocity (PV) calculation (Surface velocity X Pressure) of the PTFE seal lip. PTFE seal lips have general recommended PV limit of 150,000.

How to Avoid a Counter Rotation Failure

Rotary seals are designed such that there is a static or fixed side, most commonly the outer diameter, and a dynamic side, usually the seal lip. As the dynamic surface rotates. a standard symmetrical spring energized seal may have more friction on the dynamic lip from pressure and rotation than what the outside lip can hold. In this case, the static seal lip will break loose and become the dynamic lip. This occurrence is called counter rotation.

Surface finish and hardness specifications for the dynamic surface are made much better than the static side, so that the dynamic lip will take a long time to wear out. Basically for PTFE rotary seal lips, the harder and smoother the dynamic surface the better. When counter rotation occurs, this will most certainly cause premature failure as the rotary seal is sliding on a soft and poor surface, which wears out the seal very quickly and ultimately leads to failure.