Lockstep™ by Atlas Seals

What is Lockstep™?

Lockstep™ is a robust retention system for seals that is effective, economical, and easy to install- available only at Atlas Seals.

How Does Lockstep™ Work?

- Lockstep™ easily pushes into housing, usually by hand force only.

- No snap rings nor retaining hardware needed.

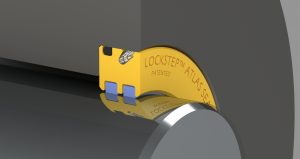

- Lockstep™’s patented angled locking barb* deforms on install, then cam-locks to housing material.

- Formed metal support ring assures seal won’t resize or become loose in housing.

- The metal barb locks in place. Lockstep™ cannot slip out of place nor rotate.

- O-ring provides robust static sealing in the Lockstep™ housing.

Why Lockstep™ by Atlas Seals?

At Atlas Seals we consider ourselves to be not a jack of all trades, but a master of one. The Lockstep™ Rotary Seal is one of our key products. This level of dedicated focus allows our experienced experts to innovate our products using input from our customers in a collaborative approach. To us, communication is key in concocting, creating, and delivering the exact product you need. We take immense pride in the fact that working with Atlas Seals is always fast, easy, and FUN!

To streamline operations along every step of the way, Atlas Seals operates out of a full capability facility. We manufacture all the seal components ourselves, with every single available material option kept in-house.

The Lockstep™ rotary seal is a piece that we take special pride in. With the Lockstep™ we can produce rapid prototypes and low volumes of seals at a lower cost per unit than in high volume orders with longer lead times. That means if you have a small order to make and you need it quickly, Atlas Seals is a perfect match for you.

PTFE rotary seals are awesome problem solvers, and they are fun to design for any application. Here at Atlas Seals, we love them! We approach our business as more of a service than a product, since each seal is designed holistically with your particular business needs in mind. You don’t need to know the technical details- leave that part to us! Just contact us now if you’re ready to work with the biggest seal enthusiasts in the industry.

However, if you are anything like us and want to “nerd out” about cool seals that work where no other seals will, we have got quite the treat for you. Keep on reading…

How Rotary Seals Work – The Lockstep™ Explained

Your typical rubber or polyurethane seals are made of soft, resilient materials. While this can be great for some seal applications, those rubbery materials are still prone to wear quickly, simply due to their soft nature.

A Rotary Seal is a metal barb-assisted, pressure-actuated sealing device that is composed of a PTFE or other high performance plastic seal jacket and a locking angled barb camlocks to the housing material. Installation is easy and can in most cases be done by hand without the use of any additional tools. As the seal is inserted into a sealing groove or gland, the angled metal barb deforms and then camlocks against the housing material. The seal itself applies a radial force against the shaft and bore. This outward force helps to maintain the contact between the lip and surface ensuring a tight seal. A formed metal support ring reinforces the structure of the PTFE seal and compensates for faults like material wear, eccentricity, or misalignment of the mating hardware components. Lastly, an O-ring provides robust static sealing within the housing.

Atlas Seals’ spring energized seals are precision machined from high performance plastics. Seal jackets made from PTFE can function across extreme temperatures ranging from cryogenic cold up to a heat of 550°F (288° C). They are practically inert to virtually all chemicals apart from a select few, such as highly reactive molten alkali metals. Elastomer O-rings provide mechanical force on the lip of the seal and are pressure activated for additional sealing strength whenever it is needed.

While the options are seemingly limitless, we promise that the perfect combination of materials for your application is out there. Finding out that perfect combination is just part of the fun for us!

Download Our Lockstep™ Brochure

Below are 6 different types of Lockstep™ rotary seals that we are proud to offer at Atlas Seals:

Example Lockstep™ Styles

STANDARD LOCKSTEP™ – External open housing, internal seal

Simple external press-in design for retaining lubrication or process fluids inside equipment.

HYGIENIC LOCKSTEP™ – External excluder in open housing

HYGIENIC LOCKSTEP™ – External excluder in open housing

The HYGIENIC LOCKSTEP™ is best suited for food, beverage, and medical equipment where cleanliness is important with frequent wash-down requirements. By using an external seal, this design entirely eliminates open cavities where contaminants may otherwise get stuck. A silicone fill may be utilized for certain designs.

LABYRINTH LOCKSTEP™ – Bearing Isolators of Efficiency Seals

The LABYRINTH LOCKSTEP™ allows for non-contacting or semi-contacting seal types to be utilized. These efficiency seals are typically used as bearing isolators or in applications with very high

BI-DIRECTIONAL LOCKSTEP™ – Retain Fluids and Exclude Contaminants

Contact between process fluids and external contaminants must be prevented to maintain the fluids’ integrity. The bi-directional lockstep works by sealing off both directions, effectively creating a double walled seal that is sure to keep contaminants out and process fluids in.

THRU-BORE LOCKSTEP™ – Simplified Housings

For simplified housings, the THRU-BORE LOCKSTEP™ is the way to go. It can be used to reduce or even eliminate complex machining operations and even reduce the number of parts in an assembly.

SPRING-LOADED LIP LOCKSTEP™ – for Heavy Duty Applications

This variant of the lockstep utilizes metal springs to increase the sealing lips contact force, which makes it a great choice for heavy duty applications. To learn more about the fascinating way spring technology works in seals, check out the Spring Energized Seals web page!

Still want to know more? Another neat thing about rotary seals is that they have an unlimited shelf life. Because our seals are precision machined by CNC Lathes in house, Atlas Seals can dream up the perfect design for you that does not require any additional tooling charges!

If you’ve made it this far, we definitely need to get in touch. Contact Atlas Seals today, and let the fun begin!