Spring Energized Seals

Why Choose Atlas Seals for Spring Energized Seals?

At Atlas Seals we consider ourselves to be not a jack of all trades, but a master of one. Spring energized seals are our core product. This level of dedicated focus allows our experienced experts to innovate our products using input from our customers in a collaborative approach. To us, communication is key in concocting, creating, and delivering the exact product you need. We take immense pride in the fact that working with us is always fast, easy, and FUN!

To streamline operations along every step of the way, Atlas Seals operates out of a full capability facility. We manufacture all the jacket and spring types ourselves, with every single available material option kept in-house.

What Are Spring Energized Seals?

Your typical rubber or polyurethane spring loaded seals are made of soft, resilient materials. While this can be great for some seal applications, those rubbery materials are still prone to wear quickly, simply due to their soft nature.

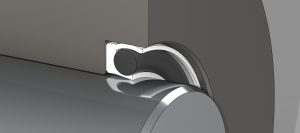

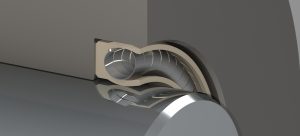

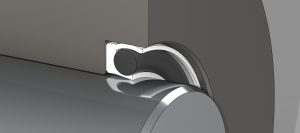

Spring energized seals instead use special plastics reinforced with metal springs to perform at higher levels. A hard plastic sleeve acts as a rigid seal, while a separate metal spring inside the seal gives the overall form a degree of resilience. By combining the hardness of the outer plastic with the resilience of the inner spring, a spring energized seal provides more consistent sealing force over a longer period of time.

Applications for Spring Energized Seals

Spring energized seals are needed when tough application conditions exceed the capabilities of elastomeric (rubber or polyurethane) seals. Some of these conditions include:

- Extremely high temperatures or extremely low temperatures

- Abrasion from high speed applications

- Highly intense pressure

- Tough environments with chemical exposure or abrasive media

- Long life or low friction requirements

The mechanics of spring energized seals operate on relatively the same principles as other radial seals. The key difference comes from the way that spring energized are precision machined from amazing materials and utilize clever metallic springs to provide a guaranteed leak-tight seal where other seals fail. We offer tons of different PTFE and high-performance plastics for the outer portion of our spring loaded seals as well as different types of springs, which we match up with each individual order based on your specific application.

Types of Spring Energized Seals

Cantiseal Spring Energized Seals

Heliseal Spring Energized Seals

Slantiseal Spring Energized Seals

O-Ring Loaded Seals

Design Profiles of Spring Energized Seals

U-Spring Cantiseal Standard

U-Spring Cantiseal Scraper

V-Spring Cantiseal B-Lip

V-Spring Cantiseal Scraper

V-Spring Cantiseal Double Bump

V-Spring Cantiseal Triple Triple

Heliseal Standard

Heliseal Scraper

Slantiseal (1)

Stem Packing Seal

L-Shape Seal

Batwing Seal

PTFE spring energized seals are awesome problem solvers, and they are fun to design for any application. Here at Atlas Seals, we love them! We approach our business as more of a service than a product, since each seal is designed holistically with your particular business needs in mind. You don’t need to know the technical details- leave that part to us! Just contact Atlas Seals now if you’re ready to work with the biggest seal enthusiasts in the industry.

However, if you are anything like us and want to “nerd out” about cool spring energized seals that work where no other seals will, we have got quite the treat for you. Keep on reading…

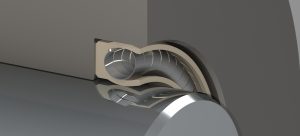

How Spring Energized Seals Work – The Nuts and Bolts of It

A spring energized seal is a spring-assisted, pressure-actuated sealing device composed of a PTFE or other high performance plastic seal jacket and a mechanical spring that’s force is positioned on the sealing lip. When the spring loaded seal is inserted into a sealing groove or gland, the spring applies a radial force against the shaft and bore. This outward force helps to maintain the contact between the lip and surface ensuring a tight seal. The spring’s force to the seal lip is a constant one which compensates for faults like material wear, eccentricity, or misalignment of the mating hardware components. When used in applications which are higher pressure than the force provided by the spring force, the system pressure then provides force to the seal lips within the spring cavity using Pascals Law- that is, equivalent to the system pressure.

Atlas Seals’ spring energized seals are precision machined from high performance plastics. Seal jackets made from PTFE can function across extreme temperatures ranging from cryogenic cold up to a heat of 550°F (288° C). They are practically inert to virtually all chemicals apart from a select few, such as highly reactive molten alkali metals. There are a huge variety of springs and materials that have different force, flexibility, and chemical resistant characteristics to match varied application requirements such as low friction in dynamic applications, or exceptionally high spring force which is commonly required for extremely cold applications. An optional added feature to our spring energized seals is an elastomer O-ring to provide mechanical force on the lips and are pressure activated just like the springs. While the options are seemingly limitless, we promise that the perfect combination of materials for your application is out there. Finding out that perfect combination for your spring energized seals is just part of the fun for us!

Below are 4 different types of spring energized seals that we are proud to offer at Atlas Seals:

Cantiseals (Cantilever Spring Loaded Seals)

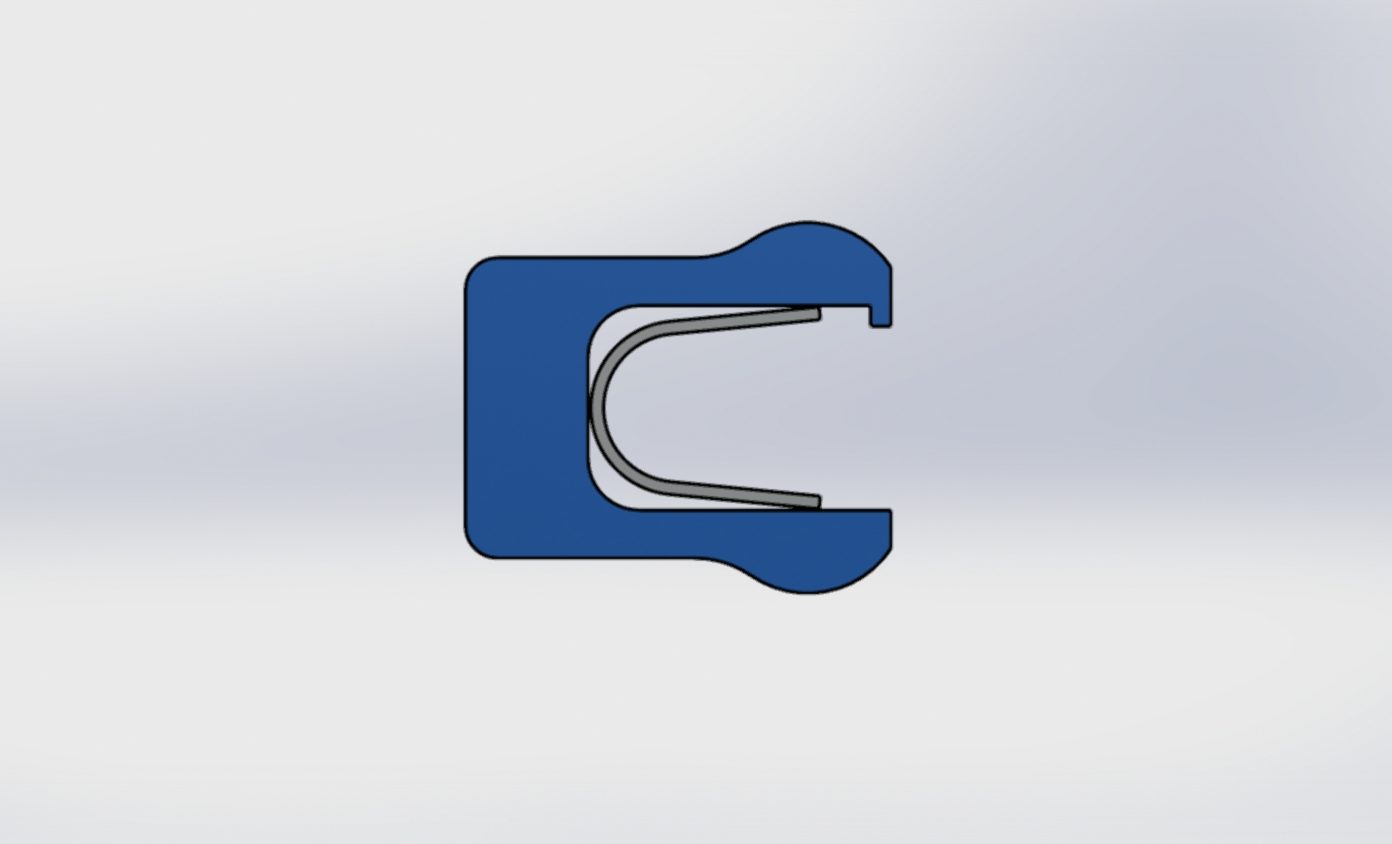

Cantiseals use a cantilever or “meander v-spring” to provide mechanical force to the seal lip. The beams of the V-shape are what provide that cantilever force on the seal lip. Cantiseals are the most common spring energized seals, as they can be used in a broad range of applications. More times than not, a Cantiseal will work in an extreme environment. V-springs can be made from corrosion resistant materials like 300 series and 17-7 Stainless Steel, or fancy nickel alloys like Elgiloy and Hastelloy for very corrosive environments.

Heliseals (Helical Wound Ribbon Spring Loaded Seals)

Heliseals use a helical wound ribbon spring. These spring energized seals are commonly used in static applications when leak-tight sealing is most important. Heliseals are best matched in sealing gasses, vacuums, and in cryogenic applications. A single Heliseal spring can provide much more force than a V-spring in the same radial cross-section size. If additional spring force is needed, we use heat-treated Elgiloy for the material to really boost the output force. The Heliseal can also be used in dynamic applications where high friction resistance is not a concern, but in such a case a Cantiseal would very well work just fine.

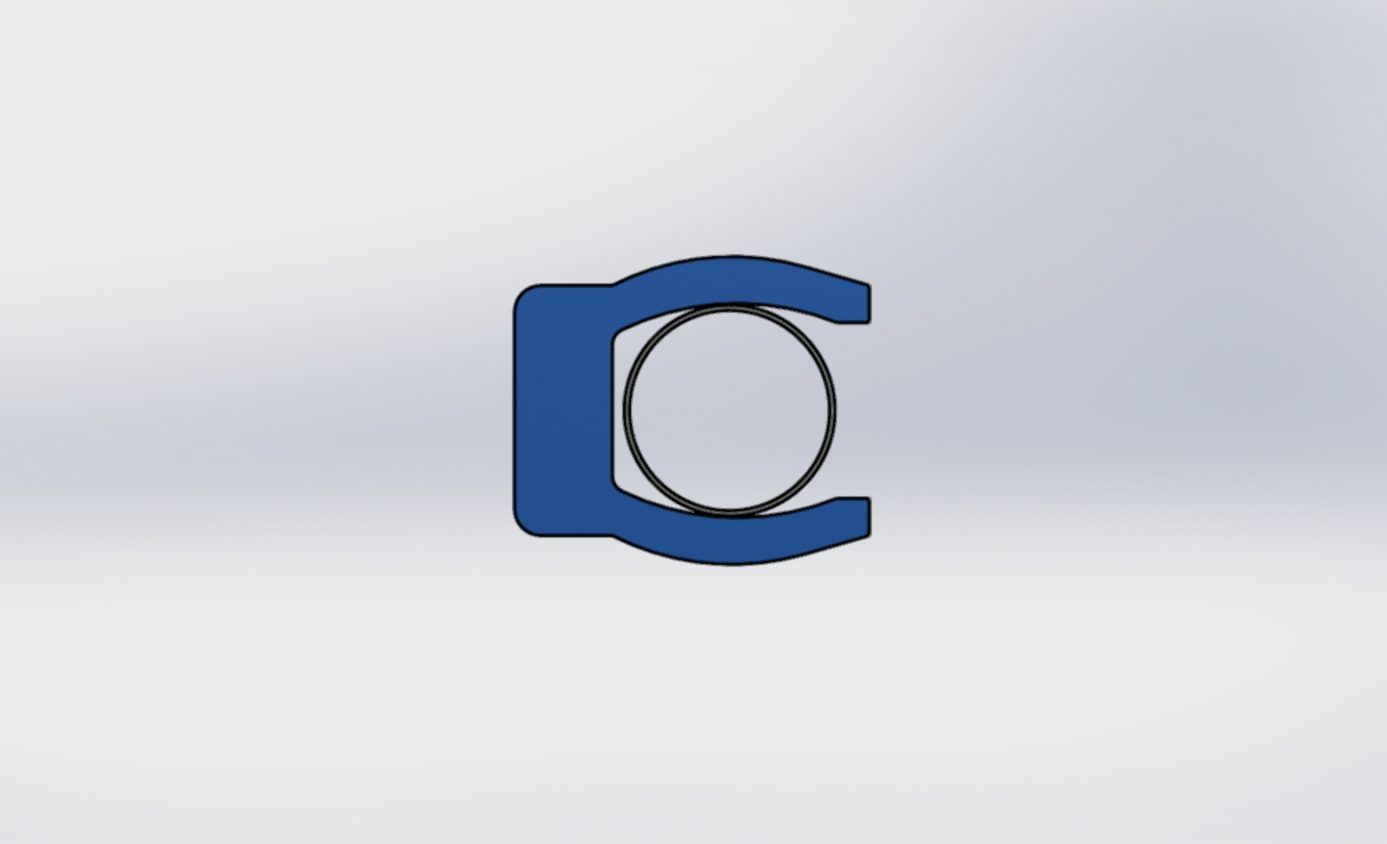

Slantiseals (Slanted-Coil or Canted-Coil Spring Loaded Seals)

Slantiseals are super cool because of how they cleverly use their spring. Each spring provides a light, near-constant spring load over a huge range of deflection. This allows for the seal lips to withstand significant wear while still keeping an efficient sealing lip load. The spring can be made from different wire diameters for different spring forces as well as different materials like 300 series stainless steel and fancy nickel alloys. Slantiseals are used in applications where very low friction is important. As cool as they are they are, their technology comes at a higher price. These specialty spring loaded seals aren’t used as commonly as Cantiseals, so we’re always stoked to see Slantiseals get their time to shine.

O-ring Loaded Seals

O-ring loaded seals operate with the same principles as the metal spring loaded seals. Unlike spring loaded seals, the system pressure energy is transferred through the elastomer O-ring to load the seal lips rather than through a metallic spring. These O-ring seals can be an economical choice when extreme temperatures and chemicals are not an issue, as we can utilize more affordable materials such as high-performance plastics and rubber.

Still want to know more? Another neat thing about spring energized seals is that they have an unlimited shelf life. And because our seals are precision machined by CNC Lathes in house, we can dream up the perfect design for you that does not require any additional tooling charges!

If you’ve made it this far, we definitely need to get in touch. Contact Atlas Seals today, and let the fun begin!