Valve Polymer Parts

Why Atlas Seals for Valve Polymer Parts and Non-Metallics?

At Atlas Seals we are experts in valves and their applications, not just seal products. Understanding the design of advanced valve seals and challenging applications enables us to solve sealing issues where others have failed. Often we consult our customers on their unique valve design needs and specifications, such as coatings and surface finishes, in order to provide a system solution that meets their application criteria.

What Are Valve Polymer Parts?

Valve polymer parts, also known as non-metallic components or seals in the context of engineering, are essential elements in various valve systems. These parts are constructed from polymers or non-metallic materials, designed to fulfill specific functions within valves, such as controlling the flow of liquids, gases, or other substances.

How Do Valve Polymer Parts Work?

In the realm of sealing technology, these non-metallic parts play a critical role in ensuring the efficient operation of valves by providing effective sealing, preventing leakage, and offering resistance to various operating conditions. Atlas Seals engineers valve polymer parts to withstand high pressure, temperature variations, chemical exposure, and wear while maintaining their integrity over extended periods of use.

Engineering Valve Polymer Parts

The choice of material for these non-metallic parts depends on the specific application, considering factors such as the type of fluid or gas being controlled, pressure, temperature, and compatibility with other materials in the valve. Common polymer materials used for these components include PTFE (Polytetrafluoroethylene), elastomers like Viton or EPDM, Teflon, polyurethane, and various other engineered plastics.

Designing these non-metallic components in valves requires a deep understanding of materials science, engineering principles, and specific operational requirements to ensure optimal performance, durability, and safety in a wide range of industrial applications.

Expertise in the selection, design, and application of these valve polymer parts is crucial for ensuring the reliability and effectiveness of valve seals across various industries, including oil and gas, petrochemical, pharmaceutical, and many others. Atlas Seals has the expertise to tackle challenges in these industries and more!

Applications for Valve Polymer Parts from Atlas Seals

Many valve polymer parts are used in applications that exceed of the performance capabilities of rubber. The specialty engineering plastics in the Atlas Seals aresenal are used where temperatures are extremely high or extremely low, where chemical exposure would destroy rubber or most plastics, and at pressures up to 80,000 PSI. Some examples of challenging seal applications that Atlas Seals has engineered valve polymer parts for include:

- Oil and gas gate valves, choke valves, ball valves, and reset relief valves

- Cryogenic valves for use in sub-zero temperatures

- Valves for light gasses such as helium or hydrogen

- Chemical processing equipment valves handling strong solvents, acids or bases

Examples of Valve Polymer Parts

Valve polymer parts encompass a range of components, such as:

- Sealing Rings and Gaskets: Sealing rings and gaskets made from polymers or non-metallic materials are utilized to create a secure seal between different components of a valve, preventing leaks. These could be O-rings, gaskets, or custom-molded seals that are specific to the valve design and its operating conditions.

- Valve Seals and Seats: Non-metallic valve seals and seats ensure proper closure and sealing of the valve to control the flow of the medium passing through it. These components are crucial in regulating the flow rate and preventing leaks when the valve is closed.

- Diaphragms: Some valves, like diaphragm valves, utilize a flexible membrane or diaphragm made from polymer materials to control the flow by flexing or deforming in response to pressure changes.

- Packing and Packing Seals: Valves often use packing, which is a material (like PTFE or graphite) wrapped around a valve stem to prevent leaks along the moving parts. Non-metallic packing valve seals provide a barrier between the stem and the bonnet of the valve.

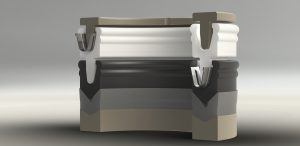

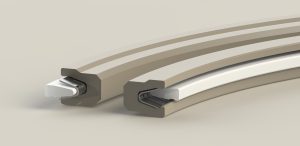

Stem Valve Seals

Ball Valve Seals

Face Valve Seal

Choke Valve Indicators

Meeting Valve Seals Standards API 6A PR2 and Annex F

Atlas Seals engineering team are the API 6A PR2 experts. With our valve polymer parts, we can help your valve pass this expensive test at pressures and temperatures which were not possible in the past. We have materials qualified to Annex F immersion H2S levels FF/HH.

API 6A PR2 and Annex F are specific standards and guidelines set by the American Petroleum Institute (API) pertaining to the requirements and testing procedures for non-metallic sealing components used in the oil and gas industry, particularly in valves and wellhead equipment. Here’s the breakdown on what you need to know about these standards when selecting valve seals for your application.

API 6A PR2 (PR-2)

PR2 stands for “Performance Requirement 2.” API 6A is a specification established by the American Petroleum Institute for the design and manufacture of valves and wellhead equipment used in the petroleum and natural gas industry. PR2 is a subset of this standard and addresses the performance requirements for non-metallic valve seals used in these high-pressure and high-temperature environments.

API 6A PR2 specifically outlines stringent requirements and testing procedures for non-metallic valve seals, such as those made from polymers, that are used in critical areas of valves and wellheads. It defines criteria related to resistance to pressure, temperature, fluid exposure, and other operational conditions. The goal is to ensure the reliability and safety of the non-metallic valve polymer parts in these high-demand applications, particularly in challenging environments like those found in oil and gas operations.

Annex F

Annex F refers to a section within API 6A that specifically focuses on the testing and evaluation of non-metallic valve seals. It details the procedures and specific tests necessary to assess the performance of these valve polymer parts under various conditions.

Annex F outlines the testing protocols to determine the suitability and durability of the non-metallic valve seals in high-pressure and high-temperature situations. The tests detailed in Annex F might include assessments for factors such as seal integrity, leakage resistance, compression set, resistance to various fluids and chemicals, and the ability to withstand cyclic loading, among others. To pass these rigorous tests, it is critical to use effective, high-quality valve polymer parts like those engineered by Atlas Seals.

Both API 6A PR2 and Annex F are critical elements within the API 6A standard, providing guidelines and specifications to ensure that non-metallic valve seals and valve polymer parts within the oil and gas industry meet stringent quality, performance, and safety criteria. Adherence to these standards is crucial for manufacturers and operators to guarantee the reliability and integrity of equipment in demanding oil and gas exploration and production environments.